The smart Trick of 24??media That Nobody is Discussing

The smart Trick of 24??media That Nobody is Discussing

Blog Article

The Only Guide for 24??media

Table of Contents24??media - QuestionsThe Definitive Guide for 24??mediaExcitement About 24??mediaThe Ultimate Guide To 24??mediaThe Single Strategy To Use For 24??media

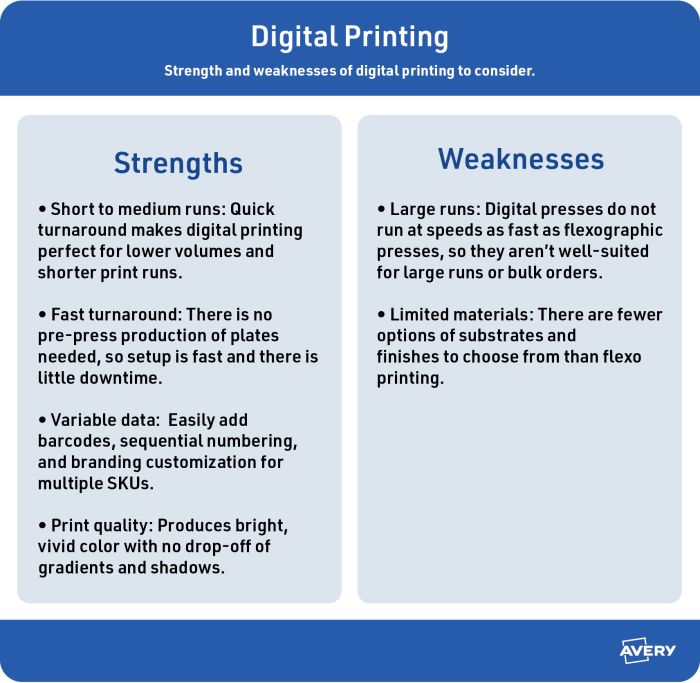

Improvements in print technology are transforming the communications playing area when it pertains to quality, affordability and sophisticated abilities. Offset printing and digital printing are the major processes whereby print work are embarked on both making use of four-color printing methods. Each choice has its advantages, providing various strategies to meet the requirements of varied manufacturing tasks.

Typically, this has actually been the most constant technique for exactly maintaining shade matches, making it perfect for print runs that just require fixed printing such as pre-printed kinds, pamphlets, leaflets, company cards, and mass postcard mailings. Due to the static nature of litho printing, it is not excellent for variable print pieces that will certainly be mailed to specific recipients such as declarations, letters, and personalized postcards.

5 Simple Techniques For 24??media

The most current innovations in print innovation are assisting to bring many of balanced out's advantages into the electronic printing globe absolutely transforming the face of modern printing! There are some essential differences in between Offset Printing and Digital Printing.

Today's digital print equipment is among one of the most innovative on the market. Below are a few of the greatest benefits of making use of digital printing: control the electronic print space, with full-color printing completed in one procedure and perfectly published directly from a print file. Without a prolonged set-up procedure, the calibration time of a specific job is reduced, contributing to quicker print time and general shipment.

The inkjet printing process has actually assisted to change the industry in addition to the high quality and rate of the output. The current inkjet modern technology can print on standard balanced out stocks with dull, silk, and glossy surfaces. High-grade digital print combined with software-managed shade management techniques includes maximum worth to publish pieces and makes manufacturing processes much more reliable than offset.

The Greatest Guide To 24??media

(https://www.callupcontact.com/b/businessprofile/24Media/9522161)

Environmentally friendly and eco-friendly inks and toners are likewise readily available for more sustainable printing. Digital print additionally removes the need to wash plates or coverings with hazardous chemicals at the end of the printing procedure.

Variable information helps services reach their specific customers and audience with uniquely-created and personalized material. As modern technology improves, the high quality of electronic printing has ended up being second-to-none, with better detail, color suit capabilities and general accuracy. Without the need to wash plates or utilize excess ink, electronic printing is also less inefficient and generally extra eco-friendly.

Conventional printing methods, such as offset lithography ("balanced out") and flexography ("flexo"), entail multiple make-ready steps to move an initial image to a substrate. These methods require the manufacturing of a collection of plates mounted on a cyndrical tube to move ink that creates the desired image when integrated on paperboard and other product packaging products. Small Volume Packaging.

Things about 24??media

Digital printing, with less relocating pieces, is extra active than offset in this respect.

Lowered set-up time conserves money on the front end. And given that these are not substantial bulk orders, smaller businesses can manage to print without having to meet the higher and extra pricey print thresholds of conventional printing.

Be sure you work together with a printing and product packaging partner that has the appropriate qualifications. While eleventh-hour printing and modification are a big benefit, electronic may not constantly be the very best method for you. Offset printing has the advantage of cost-effectiveness with large print runs, specifically those with sophisticated ornamental results and specialty layers.

How 24??media can Save You Time, Stress, and Money.

Lithographic presses make use of 2 print platesa favorable and a negativeto transfer top notch color graphics onto an appropriate substratum. The positive plate, with its smooth surface area, brings in oil-based inks and fends off water. In contrast, the negative plate, with its rough appearance, soaks up water and wards off oil. Rubber rollers are after that made use of to move the picture from home plate to the corrugated surface area.

Corrugated paper can in some cases prove to be a tough surface area to publish on, however Litho prints to a different surface area and is then laminated to it, making it simple to publish high-quality pictures. It can here are the findings be extremely regular, even for long terms. As a matter of fact, the much more you publish, the less costly the expenses end up being for Litho.

What Litho doesn't give you is exactly what Digital does, modification. Costly set up Longer turn-around No Variable Information Printing Smaller sized shade gamut, colors can be much less bright Digital printing is the process of printing digital images straight onto the corrugated substratum using a single-pass, direct-to-corrugate strategy.

Report this page